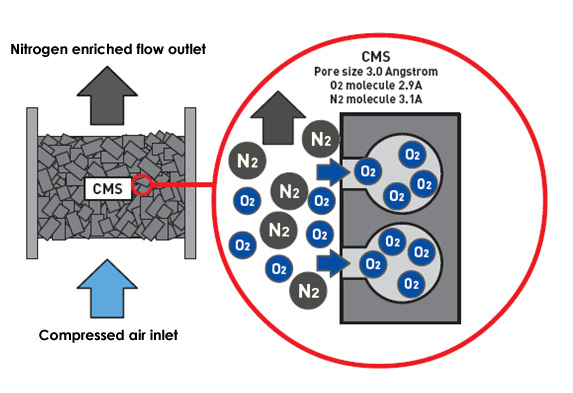

are based on the principle of selective adsorption of air on CMS molecular sieves, an acronym for Carbon Molecular Sieves.

are based on the principle of selective adsorption of air on CMS molecular sieves, an acronym for Carbon Molecular Sieves.

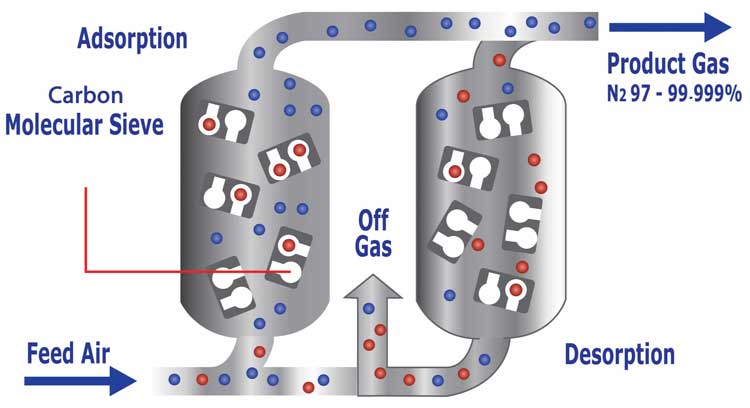

A flow of pre-filtered air feeds one of the two adsorbers, where a CMS molecular sieve system provides oxygen adsorption, allowing a nitrogen-rich stream to exit the adsorber.

The adsorption phase takes place under pressure. The adsorber is then depressurized to remove the adsorbed oxygen, while simultaneously a second adsorber is in the nitrogen production phase. This cycle is repeated continuously, allowing continuous production of nitrogen with the required characteristics to be realized.

The MICROGEN2 system uses the most advanced selective adsorption technologies, ensuring economically competitive nitrogen production and avoiding any problems of decreased or failed supply that provides full operational comfort for utilities.

Purity achieved through the use of highly accurate and reliable analyzers, which by-pass the PSA and discharge production to the atmosphere whenever out-of-standard values are detected on the produced nitrogen.

Normal maintenance every 2000/h consists only of periodic replacement of inlet air filters. Scheduled maintenance of the MICROGEN2 system is provided by qualified technical personnel belonging to the nearest Eurosider operating center. It is also possible to connect MICROGEN2 to a specialized compressor to fill cylinders up to 150 bar.

Send your request and our staff will reply as soon as possible. Thank you.